A blog dedicated to process control, industrial instrumentation and measurement & control. Weekly posts highlighting educational, informative, and new product information on all aspects of process control equipment. Courtesy of Hile Controls, Inc. | Call us at 205.620.4000

Happy Holidays from Hile Controls of Alabama

The Mark 75A Series Wafer Style Control Valves With Modular, Stackable Actuator

Mark 75A = Modular and Stackable Actuator

Mark 75A = Less Weight

Precise and Robust Gas Flow Meter for Flare Gas or Flare Stack Applications

Flare stacks are found on nearly every oil and gas installation as part of the waste gas system and as a controlled vent for high volumes of combustible gases during an upset. The pressure, volume flow, and gas composition in a flare stack can vary significantly over short periods due to their nature. Ultrasonic flow meters are well suited for reliable process control of flares due to their accurate measurement. Flow rates range from almost zero to more than 120 m/s, ensuring the optimum ratio of O2 and steam to combustion gas is maintained and that the actual volume of flared gas is determined.

Sick's FLOWSIC100 Flare-XT ultrasonic gas flow measuring instrument for flare gas measurement or flare metering is a perfect solution. The high-resolution measurement sensor and innovative design specifically for the applications in petroleum refineries, natural gas processing, and offshore and onshore oil and gas plants. Applications for the FLOWSIC100 Flare-XT include emission control or monitoring, detection of flare gas leaks, steam flow measurement, gas loss monitoring, steam injection in flare gas burning, process optimization, and condition monitoring. Gas velocity, temperature, volume and mass, mass flow rate, molecular weight, volumetric flow a. c., volumetric flow s. c., and sound velocity are all measured by the gas flow meter. The flare gas flow meter supports predictive maintenance and provides intelligent device monitoring for current and future challenges.

For more information in Alabama or Mississippi, contact Hile Controls of Alabama. Call 800-536-0269 or visit https://hilealabama.com.Thank You Veterans

"War should be the politics of last resort. And when we go to war, we should have a purpose that our people understand and support."

Colin Powell

High Performance, High Quality Sanitary Diaphragm Valves

Steriflow Valve now offers a complete line of Sanitary Diaphragm Valves including manual or air actuated, forged or cast 2-ways, ported and tandem valves, barstock zero static T-block, point of use (POU) T-block, divert tank bottom, and custom block body valves.

DOWNLOAD THE SANITARY DIAPHRAGM VALVE CATALOG HERE

- Ported, 2-way Valve - Manual or Pneumatically Actuated Forged Body 2-way Valves with Access Port

- Tandem Access Valve - Manual or Pneumatically Actuated Forged Body 2-way valves with Access Port

- Zero Static Tee Block Valve - Manual or Pneumatically Actuated Inline Barstock Zero Static Use Point Valve

- Sterile Access Block Valve - Single or Double Sterile Access, Manual or Pneumatically Actuated

- Zero Static Point of Use Valve - Standard, Compact, Manual or Pneumatically Actuated Point of Use (POU Valve)

- Divert Multi-Path, Block Valve - Manual or Pneumatically Actuated Barstock Multiple Path Diversion Valves

- Custom Block Body Valves, Clusters - Manual or Pneumatically Actuated Custom Barstock Valves and Valve Clusters

- Tank Bottom Diaphragm Valve - Manual or Pneumatically Actuated Vessel Outlet Valve

Hile Controls of Alabama can now supply you with high performance, high quality sanitary valves and accessories. Call us at 800-536-0269 or visit https://hilealabama.com.

The Eurotherm 6100A and 6180A Series Data Recorders

The Eurotherm 6100A and 6180A Series Data Recorders are specifically designed to meet industry requirements for data integrity of process records in pharmaceutical, aerospace, automotive, and food and beverage applications.

The 6100 series is self-contained, cost-effective, and trusted by customers and auditors alike, with capacity expandable to 48 precision input channels and recording intervals as short as 125ms.

To prevent packet interception or falsification, data can be encrypted during transmission to archive or backup servers using SFTP. To avoid data loss if a network connection fails, data redundancy is provided using a store and forward mechanism.

Each instrument has an easy-to-use touch-screen display that allows operators to see process data in a variety of formats. All have onboard Flash data storage, Ethernet communication, and a Compact Flash or SD Card slot. Data is stored in a tamper-proof binary format that can be used to keep secure, long-term records of your process.

The 6000 Series is suitable for a wide range of applications due to its fully featured software options and flexible I/O, which can be expanded at any time. A one-of-a-kind 'trial mode' feature removes the constraints of the purchased options, allowing you to simply 'try before you buy.'

For more information about Eurotherm products in Alabama contact Hile Controls of Alabama. Call 800.536.0269 or visit https://hilealabama.com.

Next-Generation Gear Meter Series from AW-Lake

AW-Lake Process Flow Measurement introduced its Next-Generation Gear Meter Series, which features tighter tolerances, higher resolutions, higher standard pressure ratings (6000 psi), improved accuracy, wider turndowns (100:1), and a new low-viscosity series. The Next-Generation Gear Meters include high-performance materials. They have a high chemical resistance to operate safely in abrasive or filled fluids, long service life of more than 30 years in the field, +0.1 percent repeatability, and +0.5 percent standard accuracy. These positive displacement gear meters operate in bi-directional flow applications and are unaffected by changing viscosities.

The Gear Meters provide multiple output options, including pulse, analog, and Modbus, to deliver data in required formats for PLCs, PCs, and remote displays. When combined with AW-EDGE Lake's Flow Electronics, the Next-Generation Gear Meters enable better access, understanding, and control of a process from a smartphone. Mobile and PC-based applications simplify installation, configuration, and troubleshooting.

The following items are part of the Next-Gen Series:

The JV-BB Positive Displacement Spur Gear Flow Meter replaces the JV-KG Line for measuring oil, fuel, polyurethane, brake fluid, Skydrol, and other non-abrasive, low-to-medium viscosity lubricating fluids. These gear meters are a good substitute for mag meters or oval gear technology because they have high accuracy and a wide turndown range. Units are ideal for chemical injection and dosing systems, fuel measurement, test stands, and hydraulic positioning systems.

The JV-TC Positive Displacement Spur Gear Flow Meter replaces the JV-CG line for highly accurate, cost-effective metering of paints, adhesives, sealants, light, and heavy fuel oils, resins, lubricants, and petrochemical products. The JV-TC Gear Meters are ideal for metering small-particle fluids with medium to high viscosity in filling and dosing systems, as well as two- and three-component mixing systems.

The JVH Positive Displacement Spur Gear Flow Meter measures oil, fuel, additives, and chemicals in hazardous environments. The gear meters operate in systems rated at 15,000 psi (1035 bar). Markets include offshore production platforms for chemical injection, land-based oil recovery sites, and chemical processing plants.

The JV-UF Positive Displacement Spur Gear Flow Meter is a new series for measuring flow rates of low viscosity fluids such as kerosene, fuels, and odorants at very low flow rates as low as two cc/min. The JV-UF Gear Meters are ideal for chemical injection skids, fuel, and solvent measurement, liquid seal dispensing, batching, and dosing.

Hile Controls of Alabama

http://hilealabama.com

800.536.0269

Fiber Optic Pipeline Leak and Intrusion Detection Utilizing Rayleigh Backscatter and Time of Flight Technologies

Fiber Optic Sensing is a newer aspect of industrial instrumentation that enables real-time measurements of long assets such as pipelines, conveyors, and perimeters. The Praetorian Fiber Optic Sensing System from HAWK is the only system on the market with a single interrogator that measures Distributed Acoustic Sensing (DAS), Distributed Temperature Sensing (DTS), and Distributed Strain Sensing (DSS) all in a single enclosure. The benefit of making these measurements in a single system is those parallel measurements of strain, temperature, and acoustics can be made in their most basic form in real-time by a single processor, allowing for better pattern recognition and faster acquisition and confirmation of events. Another benefit of HAWK's Praetorian Fiber Optic Sensing System is that it ignores false alarms, resulting in one of the market's most accurate and dependable systems. This ground-breaking technology can safeguard assets, equipment, and perimeters. HAWK's Fiber Optic System is modular in design and can monitor up to 50 miles in real-time, 24 hours a day, seven days a week. This type of intelligent monitoring is critical for efficient operation and the protection of valuable assets.

For more information in Alabama and Mississippi contact Hile Controls of Alabama. Call 800-536-0269 or visit https://hilealabama.com.

Kayden Instruments CLASSIC™ Series Thermal Dispersion Flow, Level, Interface & Temperature Switches & Transmitters

Kayden Instruments is a leading manufacturer of flow, level, interface & temperature products in the process control community.

Their products assist organizations in the global oil and gas, pipeline, power, mining, chemical, transportation, water and wastewater, food, manufacturing, pharmaceutical, plastics, pulp & paper, and semiconductor industries to improve process efficiency.

Features that make their CLASSIC™ 800 standout amongst the competition:

Patented Design

- Kayden’s patented designs provide the ultimate performance and features package for flow, level, interface, and temperature sensing.

- Kayden’s products combine precision welded, highly accurate sensors, extremely rugged enclosures, and advanced digital electronics.

- The CLASSIC 800 Series combines the failure resistance inherent in Thermal Dispersion technology with the performance and features usually reserved for much more expensive instruments.

Universal Power Input

- Some manufacturers require upfront specifying of all options, such as relay-energized mode, at the time of order. Still, with the Kayden CLASSIC 800 series, you can select your choice of operation modes by simply pushing a few buttons.

- The universal power input capability of the Kayden CLASSIC 800 series provides flexibility for use in all power input situations.

Discrete & Analog Outputs

- Modbus registers via RS-485 4-20 mA analog representation of Thermal Signal.

- Two SPDT sealed relay contacts rated @ 4 amps resistive 230 VAC or 24 VDC maximum.

Adjustments

- Adjustable Set Point Deadbands

- 4 Adjustable Independent Switch Point Timers

Advanced Diagnostics

- Kayden’s CLASSIC 800 series uses an advanced microprocessor to perform continuous self-test diagnostics on the electronics and the sensor elements.

- Any open or shorted connection will result in a FAULT indication that deactivates all relays and disables the heater circuitry.

- An internal watchdog circuit ensures that the microprocessor code is performing as expected, and a secondary external watchdog circuit confirms the microprocessor itself is functioning. Both circuits force the contacts open, illuminate the Fault LED, and force the heater off in a malfunction, preventing the possibility of a “run-away” heater or a high thermal offset.

Intelligent User Controls

- The Kayden CLASSIC 800 series Display Panel features very bright LED indicators for easy viewing even in direct sunlight.

- An adjustable power-on Start-up Bypass Timer is accessible from the Display Panel for low-flow alarm pump protection applications. This feature makes it possible to disable a pump on low flow and have it automatically restart after a predetermined time in the event of a power interruption.

- Four adjustable delay timers introduce repeatable time delay into the (setpoint) relay trip function. For example, in a pump protection application, this function will shut down the pump after the switch sensor has gone “dry” for the pre-set time (delay) limit.

- The Kayden RCM (Remote Communications and Monitoring) Software allows all the settings to be configured remotely and saved as a file, transmitted as an email attachment, and printed for future reference.

- The Kayden RCM Software includes the option of locking the CLASSIC 800 Series Display Panel to eliminate field adjustments or tampering.

- Modbus allows multiple Kayden units to be connected to the same communications bus (via RS-485) and monitored simultaneously.

For more information about Kayden in Alabama, Mississippi, Western Tennessee, and Florida, contact Hile Controls of Alabama. Call them at 800-536-0269 or visit their website at https://hilealabama.com.

Combating Droop In Self Contained Pressure Regulators

Sometimes referred to as the ‘Proportional Band’ or ‘Offset’, droop is an inherent characteristic in all self-operated and pilot-operated regulators. Droop is a decrease in outlet pressure from the set value due to an increase in media flow rate.

Download this white paper on combating droop in self-contained pressure regulators. Learn about what you need to consider, what the droop effective is, typical applications, how to reduce droop and how to choose the right valve.

Hile Controls of Alabama

http://hilealabama.com

800.536.0269

The Hawk Measurement OptioLaser L100 and L200 Laser Level Transmitters

The Hawk Measurement OptioLaser L100 and L200 Laser Level Transmitters are perfect for measuring the level, distance, and the location of solid and liquid surfaces.

The OptioLaser L100/L200 is a non-contact laser sensor used to measure the distance to solid and liquid surfaces, slurries, or murky water. Solid surfaces can be anything from a metal plate on the side of an overhead crane to the top of material stored in a silo. With an easy-to-use menu system, the OptioLaser is configurable for either distance or level measurement. The high accuracy, long-range, and fast update rate make this the ideal sensor for many different applications.

The OptioLaser uses a unique laser that has a very narrow beam that can measure long and short distances at practically any angle. Furthermore, the OptioLaser L100/L200 is made entirely of stainless steel and is exceptionally tough and perfect for the harshest conditions. Their accuracy and durability make the OptioLaser ideal for a wide range of applications and industries.

The sensors are highly effective in various applications, including blocked chute detection, material handling, positioning, plastic pellet silos, conveyor belt edge control, ore pass levels, and bin levels.

The OptioLaser L100/L200 Laser Level Transmitters are fully programmable and come with user-friendly software. The lasers, which can measure distance or level, are particularly valuable in applications such as mining.

The OptioLaser S200 Laser Sensor monitors tripper positioning, blockage detection, barrier detection, machine detection, stockpile monitoring, and point-level measurement. Typical applications consist of block chute detection, stockpile monitoring, tank and silo level, collision detection, and truck or machine detection.

The Hawk Measurement OptioLaser L100 and L200 are the ideal solution for a wide range of industrial applications such as plastics, mining, aggregates, water and wastewater, oil and gas, pulp and paper, pharma, food and beverages, and chemicals and petrochemicals.

Hile Controls of Alabama

http://hilealabama.com

800.536.0269

The ABB LST200 Ultrasonic Level Transmitter

The ABB LST200 ultrasonic level transmitter makes accurate level measuring easier than ever. Its sophisticated algorithm eliminates noise interference to provide ultra-stable level measurement in even the most demanding conditions. The LST200 delivers lower total lifetime expenditure on purchasing, installation, and maintenance due to its user-friendly interface, modular design, and diagnostic messages, making it the simplest level measurement option for water and wastewater, power generation, and pulp and paper industries.

For more information about ABB Level Measurement contact Hile Controls of Alabama. Call 800.536.0269 or visit https://hilealabama.com.

Details of the Eurotherm Series 2000 Obsolescence and the EPC3000 Replacement

Over the last 25 years, the 2200 and 2400 controllers have been two of Eurotherm's longest-running and best-selling control offerings. They have proven themselves to be highly versatile and reliable for all sorts of applications. However, many have changed since the '90s, including significant advances in microelectronics technology. Eurotherm incorporated these advances into new and improved offerings.

That's why Eurotherm decided to make the 2200 and 2400 series controllers obsolete, effective January 31st, 2021, with repair and servicing for these ranges available until 2025.

As a replacement for these ranges, Eurotherm recommends the EPC3000 series of programmable controllers. They offer the same functionality you've come to expect, along with additional improvements to help meet the needs of today. They also feature very similar wiring to both the 2200 and 2400 series controllers. They are available in the exact three DIN sizes.

Installing the controller into existing panels is friendly and straightforward. Plus, the EPC3000 series has been designed with cybersecurity in mind and certified to meet the stringent requirements of Achilles Communications Robustness Testing Level 1. You'll also benefit from enhanced precision control, exceptional thermal stability, and noise rejection. It's also more user-friendly, featuring a graphical wiring environment to help create applications. Users can select the function blocks they wish to use in their application and then connect them using 'soft wiring .' There is a pictorial view of the configuration. Ethernet communications are supported via a standard RJ45 connector, providing fast access to the process, and diagnostic information as Eurothermll as connectivity to an external PLC or a plant SCADA.

The EPC3000 programmable controller offers exceptional value and packs many features typically only available in high-end control offerings. Whatever your process, the EPC3000 range can help you achieve the required stability, accuracy, and repeatability.

Hile Controls of Alabama

http://hilealabama.com

800.536.0269

Precise Real-Time Dry Flow Measurements for Landfill Pollution Reporting with Kurz Instruments Flow Meter

Landfill gas (LFG) is a natural byproduct of the decomposition of organic materials in landfills. LFG is composed of roughly half methane (the primary component of natural gas), half carbon dioxide (CO2), and a trace of non-methane organic compounds. Over a 100-year cycle, methane is a potent greenhouse gas that traps heat in the atmosphere 28 to 36 times more effectively than CO2.

Municipal solid waste (MSW) landfills are the third-largest source of human-related methane contamination in the United States, accounting for approximately 15.1% of total emissions in 2018.

LFG pollution and methane migration into the atmosphere leads to local smog and global climate change. Instead of escaping into the atmosphere, LFG can be collected, converted, and used as a renewable energy resource.

LFG is removed from landfills using a network of wells and a blower/flare (or vacuum) system. The gas's ultimate use depends on to practicality of how the extracted gas transports to a central location where it can be processed and treated and then be flared or used in an LFG energy project.

Many landfills install gas control controls due to regulatory requirements. The federal government enforces legislation that governs the use and maintenance of landfills. These regulations aid in controlling ozone precursors (volatile organic compounds and nitrogen oxides), methane, NMOCs, and odorous compounds from landfill gas emissions, which harms human health and the atmosphere.

Thermal flow meter technology is perfect for these applications because of its low-pressure drop and ability to calculate very low flow volume. On the other hand, standard thermal flow meters generally do not perform well in condensing gas conditions, and applications such as landfill methane recovery systems cause problems with standard thermal flow meters.

The unpredictability of moisture levels caused by leachate, rain, temperature, and humidity exacerbates the accuracy issues associated with wet gas flow measurements. A solution is the Kurz WGF flow meter. It is perfect for use in wet gas applications. Kurz allows you to quantify gas flow precisely and provide real-time dry flow measurements for pollution reporting (federal, state, local regulations, greenhouse gases, and the Landfill Methane Rule).

For more information about Kurz Flow Meters in Alabama, Mississippi, and the Florida Panhandle, contact Hile Controls of Alabama. Call them at 800-536-0269 or visit their website at https://hilealabama.com.

Introducing the LowFlow MK708MAX Control Valve

The MK708MAX is a valuable addition to our line of precision globe-style control valves giving our control valve line the ability to get into higher flow applications. The LowFlow MK708Max will have a CV range from 6.5-10 (5.6 - 8.65kv), utilize the 35M actuator, and allow for a maximum inlet pressure of 1,000psi. All accessories that would normally be offered on a MK708 will be offered for the MK- 708MAX.

DOWNLOAD THE MK708MAX DATASHEET HERE

MK708MAX Product Highlights

- Capable of handling 1,000psi (69 bar) inlet pressures at 100°F (38°C) - the competition only goes up to 720psi (50bar)

- CVs ranging from 6.5-10 (5.6 - 8.65kv)

- Body Material Options- Bronze, Carbon Steel, and Stainless.

- Available in 1” (DN25)

MK708MAX Applications

High Pressure Gas, Aerospace/Fuel Testing, Refining/Chem/Petrochem, Pilot Plants/R&D

For more information about the MK708MAX in Alabama, Mississippi and the Florida Panhandle, contact Hile Controls of Alabama. Call 800.536.0269 or visit https://hilealabama.com.

Webinar: Advantages of Ultrasonic Technology for Flare Apps in the Chemical, Petrochemical & Refinery Industries

Flare stacks are used on nearly every oil and gas installation as part of the waste gas system and as a regulated vent for high volumes of combustible gases during an upset. The pressure, volume flow, and gas composition in a flare stack can vary significantly over short periods. Since its inception in the 1920s, ultrasonic technology has evolved for various applications, including the calculation of flare gas flow. Ultrasonic flow meters are well suited for reliable process monitoring of flares due to their precise measurement of flow rates ranging from almost zero to more than 120 m/s. Using ultrasonic flow meters ensures that the optimal ratio of O2 and steam to combustion gas is maintained and proper calculation of the actual amount of flared gas.

On April 22, 2021, ultrasonic flow meter manufacturer SICK Sensor Intelligence and industry publication Chemical Engineering are presenting "Advantages of Ultrasonic Technology for Flare Apps in the Chemical, Petrochemical & Refinery Industries."

Please reserve the date and join SICK Sensor Intelligence and Chemical Engineering for this webinar to learn about the latest developments and benefits of using ultrasonic technology for flare applications.

REGISTER HERE NOW!

(https://www.bigmarker.com/access-intelligence4/SICK-webinar)

Sanitary Control Valves with O-Ring Stem Seals: The Steriflow FBCV-OR

Diaphragm type control valves are found on WFI (Water for Injection) systems for end of loop backpressure control, on buffer dilution skids, and filtration skids for pressure and flow control and chromatography elution flow control.

O-ring stem seals (what ASME BPE defines as sliding stem seals) are usually specified for control valves on clean air and gas and liquid clean utility applications like USP Purified water and some CIP fluids.

The FBCV O-Ring Series by Steriflow meets the rigid specifications for sanitary process control valves for customers who prefer an O-ring style stem seal. This valve series is suitable for various cosmetic, dairy, and food and beverage industries. Conforming to 3A guidelines, the FBCV is ideal for a wide range of flowing media in both the utility and process areas of sanitary systems.

High rangeability, characterized trim, high capacities, superior temperature and pressure ratings, and a selection of sealing methods make the FBCV sanitary control valve ideal for liquid, gas, and steam services. Whether the need is to control pressure, temperature, flow, pH, or another variable, the FBCV is the correct valve for your process.

DOWNLOAD THE FBCV-OR DATASHEET HERE

Hile Controls of Alabama provides reliable sanitary valves and other products that can be trusted by food, beverage, dairy, health and beauty producers. Hile provides products used in various steam applications including plant steam, filtered steam, clean steam and pure steam. Products include back pressure regulators, pressure regulators, steam traps, check valves, butterfly valves, ball valves and other ancillary products.

Infrared Pyrometers for Industrial Temperature Measurement

Temperature is one of the most commonly measured process variables in manufacturing operations. Proper temperature regulation and control are critical to product quality and process productivity.

Many applications use contact devices like thermocouples and RTDs. Still, these devices are too often inaccurate, too slow, difficult to use or require frequent replacement, creating process downtime and reducing productivity. For many applications, infrared pyrometers are the perfect solution because they can accurately and reliably measure a target’s temperature without contact.

Wavelength selection can dramatically reduce or even eliminate errors due to optical obstructions, emissivity variation, background reflections, and misalignment. Williamson offers six different types of infrared temperature measurement technology with various wavelength options, multiple optical configurations, temperature spans, and accessories to ensure each infrared thermometer receives the perfect setup for each application.

To download a Williamson pyrometer brochure, visit this link.

Level Measurement - Floating Roof Terminals

Designed for industrial applications and harsh environments., the LLT100 provides continuous, non-contact level measurement capabilities for process automation and inventory management.

Jordan Valve Express Program and Next Business Day Shipping

Jordan Valve manufactures pressure regulators, back pressure regulators, and temperature regulators for customers worldwide. They also provides the fastest, most responsive delivery options, with best-in-class lead times and precise on-time delivery.

The Jordan Valve Express Program gives you the ability to get the materials you need when you need them. Most of Jordan's regulator, control valve, and tank blanketing products are ready for shipment on the next business day.

For more information about this program in Alabama and the Florida Panhandle, contact Hile Controls of Alabama. Call 800.536.0269 or visit https://hilealabama.com.

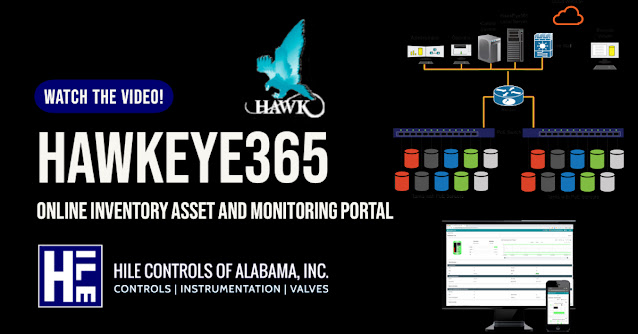

HawkEye365 Online Inventory Asset and Monitoring Portal

The HawkEye365 Online Inventory Asset and Monitoring Portal is a complete remote and in-plant measurement and monitoring system. Unlike anything on the market today, this system is uniquely different due to the communications capabilities and compatibility with HAWK's Power over Ethernet level sensors. The advantages to Power over Ethernet connectivity are secure in-plant and remote monitoring, as well as remote sensor setup, diagnostics and troubleshooting abilities. The HawkEye365 portal is not only compatible with PoE transmitters, but is also sensor agnostic and can monitor any type of field device such as level, flow, pressure, temperature and pH. The multiple communication methods include RS485, HART, Modbus, Ethernet TCP/IP, Cellular, Bluetooth and PoE. For more information in Alabama, Mississippi, Western Tennessee and the Florida Panhandle, call:

Precision Turbine Flow Meters Assist in Lower NOx on Gas Turbines

As smaller power sources, gas turbine generators are cost-effective solutions. Packaged as systems, they offer flexibility and simplicity with a capacity of 20 MW to over 1000 MW. The gas turbine engine is proven and reliable technology that allows for relatively rapid installation of a complete package almost anywhere.

Regulatory agencies and manufacturers are examining emissions standards that further restrict the release of pollutants into the atmosphere and are increasingly developing systems to meet ever-tighter standards. In gas turbines, nitrogen oxides (NOx) resulting from the combustion of fuel and air, and any nitrogen component, are the primary pollutants produced. The turbine's firing temperature and the fuel used heavily influence a standard gas turbine's NOx emission.

One method of NOx reduction is water injection, used since the 1970s. Systems inject water vapor directly into the combustor of a gas turbine, reducing the flame's temperature, which decreases NOx emissions in turn.

By injecting demineralized water directly with the fuel (natural gas, fuel oil, etc.), it achieves a reduction of turbine firing temperature, directly correlating to a decrease in NOx emissions. Demineralized water minimizes scaling and build-up in the nozzles and the combustion chamber. As the generator's load increases, additional water maintains the turbine firing temperature low enough to reduce NOx emissions to about 25ppm. The turbine flow meter measures the supply water flow rate to the nozzle injector manifold to control the feedwater valve position while monitoring the firing temperature. This application requires a very accurate flow meter for a precise control scheme.

The Flow Technology FT Series turbine meter with the LA-5 linearizing electronics and an extended range calibration to give a turndown of 100:1 over the flow range fits the bill. Available with either meter-mounted or remote-mounted electronics and high temperature amplified pickoffs that eliminate noise generated by the floating (non-grounded) electrical system of the turbine generator. Additionally, the FT Series turbine meter can be placed inside the generator room due to its compact size and durability under extreme conditions.