The HawkEye365 Online Inventory Asset and Monitoring Portal is a complete remote and in-plant measurement and monitoring system. Unlike anything on the market today, this system is uniquely different due to the communications capabilities and compatibility with HAWK's Power over Ethernet level sensors. The advantages to Power over Ethernet connectivity are secure in-plant and remote monitoring, as well as remote sensor setup, diagnostics and troubleshooting abilities. The HawkEye365 portal is not only compatible with PoE transmitters, but is also sensor agnostic and can monitor any type of field device such as level, flow, pressure, temperature and pH. The multiple communication methods include RS485, HART, Modbus, Ethernet TCP/IP, Cellular, Bluetooth and PoE. For more information in Alabama, Mississippi, Western Tennessee and the Florida Panhandle, call:

A blog dedicated to process control, industrial instrumentation and measurement & control. Weekly posts highlighting educational, informative, and new product information on all aspects of process control equipment. Courtesy of Hile Controls, Inc. | Call us at 205.620.4000

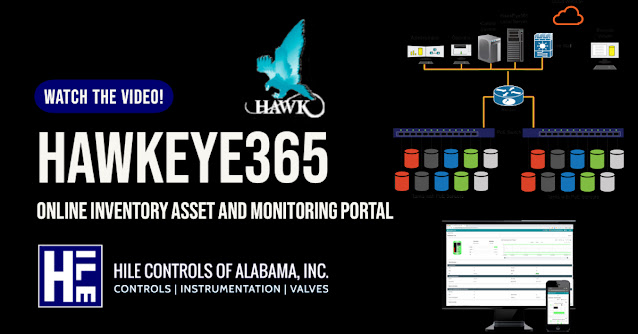

HawkEye365 Online Inventory Asset and Monitoring Portal

The HawkEye365 Online Inventory Asset and Monitoring Portal is a complete remote and in-plant measurement and monitoring system. Unlike anything on the market today, this system is uniquely different due to the communications capabilities and compatibility with HAWK's Power over Ethernet level sensors. The advantages to Power over Ethernet connectivity are secure in-plant and remote monitoring, as well as remote sensor setup, diagnostics and troubleshooting abilities. The HawkEye365 portal is not only compatible with PoE transmitters, but is also sensor agnostic and can monitor any type of field device such as level, flow, pressure, temperature and pH. The multiple communication methods include RS485, HART, Modbus, Ethernet TCP/IP, Cellular, Bluetooth and PoE. For more information in Alabama, Mississippi, Western Tennessee and the Florida Panhandle, call:

Precision Turbine Flow Meters Assist in Lower NOx on Gas Turbines

As smaller power sources, gas turbine generators are cost-effective solutions. Packaged as systems, they offer flexibility and simplicity with a capacity of 20 MW to over 1000 MW. The gas turbine engine is proven and reliable technology that allows for relatively rapid installation of a complete package almost anywhere.

Regulatory agencies and manufacturers are examining emissions standards that further restrict the release of pollutants into the atmosphere and are increasingly developing systems to meet ever-tighter standards. In gas turbines, nitrogen oxides (NOx) resulting from the combustion of fuel and air, and any nitrogen component, are the primary pollutants produced. The turbine's firing temperature and the fuel used heavily influence a standard gas turbine's NOx emission.

One method of NOx reduction is water injection, used since the 1970s. Systems inject water vapor directly into the combustor of a gas turbine, reducing the flame's temperature, which decreases NOx emissions in turn.

By injecting demineralized water directly with the fuel (natural gas, fuel oil, etc.), it achieves a reduction of turbine firing temperature, directly correlating to a decrease in NOx emissions. Demineralized water minimizes scaling and build-up in the nozzles and the combustion chamber. As the generator's load increases, additional water maintains the turbine firing temperature low enough to reduce NOx emissions to about 25ppm. The turbine flow meter measures the supply water flow rate to the nozzle injector manifold to control the feedwater valve position while monitoring the firing temperature. This application requires a very accurate flow meter for a precise control scheme.

The Flow Technology FT Series turbine meter with the LA-5 linearizing electronics and an extended range calibration to give a turndown of 100:1 over the flow range fits the bill. Available with either meter-mounted or remote-mounted electronics and high temperature amplified pickoffs that eliminate noise generated by the floating (non-grounded) electrical system of the turbine generator. Additionally, the FT Series turbine meter can be placed inside the generator room due to its compact size and durability under extreme conditions.