PID is short for "proportional plus integral and derivative control", the three actions used in managing a control loop. Process loop controllers use one, two or all three of these to optimally control the process system. PID control is used in a wide variety of applications in industrial control and process system management.

Download "Principles of PID Control and Tuning" from the Hile Controls website here.

Courtesy of Eurotherm. Eurotherm offers a wide range of single & multi-loop PID controllers.

A blog dedicated to process control, industrial instrumentation and measurement & control. Weekly posts highlighting educational, informative, and new product information on all aspects of process control equipment. Courtesy of Hile Controls, Inc. | Call us at 205.620.4000

Tutorial on Setting Up the Jordan Valve Mark 70SP Series Sliding Gate Control Valve

The Jordan Mark 70SP Series is a line of pneumatically operated diaphragm control valves that combine multiple spring actuators with the precision of Jordan Valve's advanced sliding gate seat for closer control and greater accuracy.

Consisting of a modulating disc and stationary plate, the sliding gate seat components are slotted with multiple orifices that align to provide the precise flow needed to maintain the process requirements. The valve strokes in a fraction of the travel required by conventional control valves for rapid correction of any deviation from the process setpoint.

Jordan's unique sliding gate control valve trim teams up with pressure, temperature pH, level, or flow controllers for fast response, long term reliability, and high levels of accuracy on steam, gas, liquid and chemical services.

For more information about all Jordan Valve products, contact Hile Controls of Alabama by calling 800-536-0269 or visiting https://hilealabama.com.

The ABB LMS200 Magnetic Level Gauge Switch

If you're looking for reliable liquid level detection from a non–invasive, non–contact, and economical device, ABB has a solution you need to consider.

If you're looking for reliable liquid level detection from a non–invasive, non–contact, and economical device, ABB has a solution you need to consider.

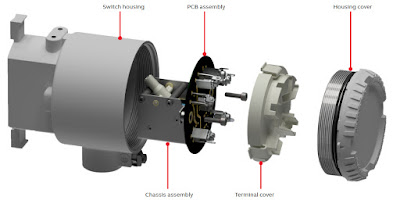

ABB’s magnetic level gauge switches provide safe and reliable liquid level detection and process control when integrated externally on the KM26 series magnetic level gauges and LS series products. The LMS200 series are non–invasive magnetically actuated electrical switches that provide complete isolation from the process fluid by coupling with the magnetic floats and attraction sleeves already present in the ABB KM26 and LS series magnetic level gauge.

This passive, method of coupling facilitates safe operation, while also eliminating the need for costly seals, diaphragms, and process connections commonly associated with point level switch technology. The superior design enables the setpoint to be adjusted without any changes to process piping, resulting in level switches that are quickly deployed, readily adjustable, and easy to maintain.

|

| LMS200 Magnetic Level Gauge Switch (exploded view) |

|

| Wiring |

|

| Mounting |

For more information on the LMS200 Magnetic Level Gauge Switch, or any ABB process level product, contact Hile Controls of Alabama.

https://hilealabama.com

800-536-0269

Subscribe to:

Posts (Atom)