If you're looking for reliable liquid level detection from a non–invasive, non–contact, and economical device,

ABB has a solution you need to consider.

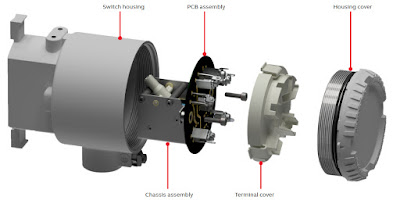

ABB’s magnetic level gauge switches provide safe and reliable liquid level detection and process control when integrated externally on the KM26 series magnetic level gauges and LS series products. The LMS200 series are non–invasive magnetically actuated electrical switches that provide complete isolation from the process fluid by coupling with the magnetic floats and attraction sleeves already present in the ABB KM26 and LS series magnetic level gauge.

This passive, method of coupling facilitates safe operation, while also eliminating the need for costly seals, diaphragms, and process connections commonly associated with point level switch technology. The superior design enables the setpoint to be adjusted without any changes to process piping, resulting in level switches that are quickly deployed, readily adjustable, and easy to maintain.

|

| LMS200 Magnetic Level Gauge Switch (exploded view) |

|

| Wiring |

The LMS200 provides double–pole, double–throw (DPDT) switching in the form of two isolated normally open or normally closed contacts. Since the switch is configured in a double pole double throw configuration, two separate devices can be controlled with the same switch. The current switching capacity of the switch allows for a wide variety of devices to be switched as long as the stated limits are not exceeded. Since the LMS200 is magnetically actuated, it is suited for any application where it is necessary to sense the passing of a magnetic float on a KM26, or similar chamber, attached to a vessel containing fluid. This will provide for the detection of a start/stop trip point of either a total or interface level of any vessel. These trip points can be used for alarms or activating a pump motor starter relay.

|

| Mounting |

The LMS200 is mounted using two standard stainless steel clamps that pass over the tabs mounted to the switch housing The clamp is then fastened to the KM26, or similar chamber. The switch can be easily positioned by loosening the clamp with a screwdriver and sliding the switch to the correct position on the chamber. Other switches can be added at any time, without the concern for additional process piping or valves.

For more information on the

LMS200 Magnetic Level Gauge Switch, or any

ABB process level product, contact

Hile Controls of Alabama.

https://hilealabama.com

800-536-0269